Product Description

PVC Mesh for Christmas Motif Lights solves three common field issues: sun, cold, and slow installs.

Many wraps crack or fade when exposed to rooftop sun and freezing temps. Complex designs also slow down crews. Plus, yearly reuse means storage worries and rework costs.

We support OEM&ODM to meet customized needs.

Our mesh is light, flexible, and weather-resistant. It speeds install and stays stable over time.

Why Choose This Material:

- Lighter Weight: The mesh structure cuts frame stress on large motifs

- UV Protection: Anti-UV and anti-yellowing additives keep colors bright

- Easy Wrapping: Pairs well with metal frames and metallic tinsel—less rework

- Roll Packaging: Simple to transport, store, and cut on site or in training classes

- Reliable quality: can still work stably under extreme temperature conditions from -20°C to 70°C

PVC Mesh for Christmas Motif Lights works with motif frames, gutter lights, neon flex, and soffit lines. Crews use standard clips, ties, or wires to fix it. So the process stays the same—no extra training needed.

We offer flame-retardant (FR/V0/V2) versions for malls, theme parks, and public events. This meets safety codes.

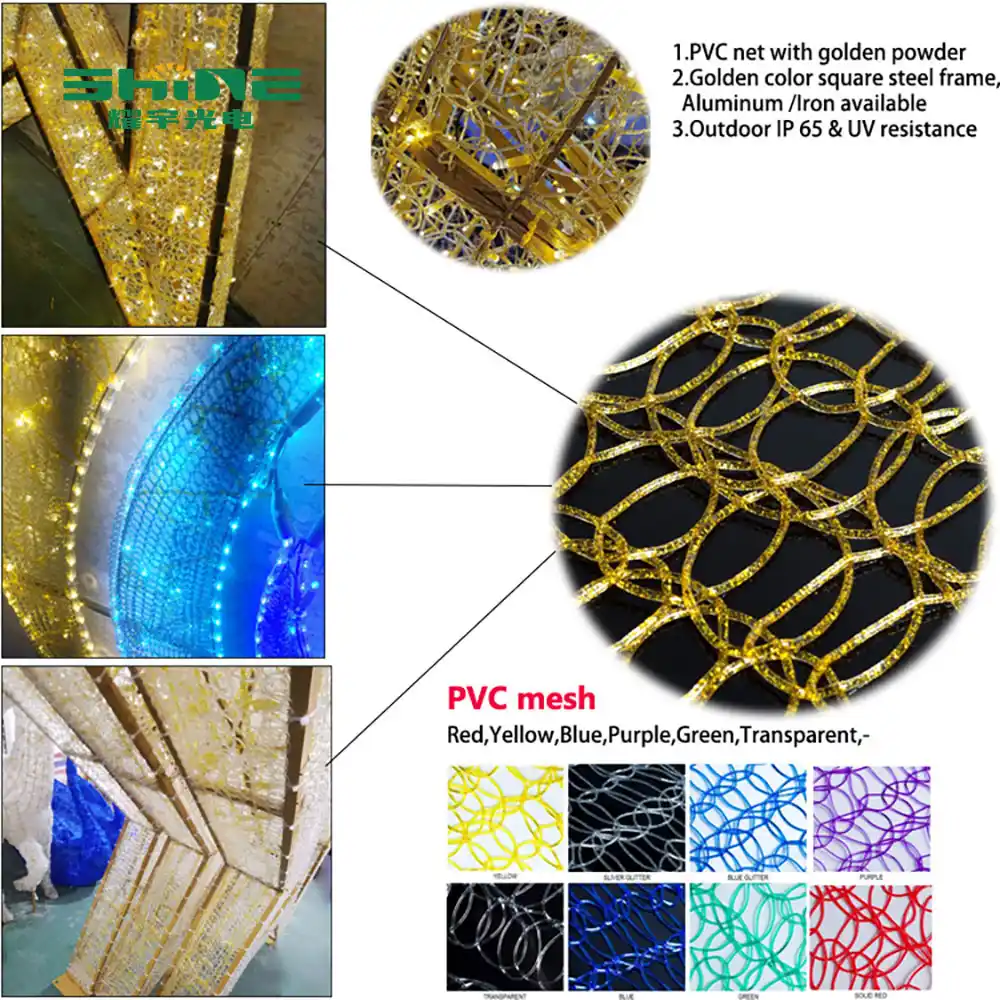

Colors available: red, white, yellow, etc. Match your brand or theme fast.

For factories producing 3D motif light frames, the mesh ships in bulk rolls to support stable upstream supply for a 3D motif light factory program.

Why Choose Us

- Years of Focus: We understand motif lights and roofline projects deeply

- Stable Supply: Consistent raw materials and masterbatch systems ensure batch-to-batch quality

- Engineering Support: Engineers coordinate from selection to sampling to mass production

- Peak Season Ready: We forecast and prepare materials for your procurement and construction plans

Request a Quote | Talk to an Engineer

Integration & Compatibility

PVC Mesh for Christmas Motif Lights fits roofline, eave, gutter, and motif frames without new tools.

System Compatibility:

- Eave/roofline lights, gutter lights, icicle lights

- Neon flex/rope light frames

- Silhouette/motif light structures

Structural Compatibility:

- Wraps aluminum, wire, and composite frames

- Handles corners, curves, and edges smoothly

Process Compatibility:

- Keep existing steps: cut, wrap, fix, adjust, finish

- Rolls dispense by meter for warehouse control

- Leftover material rolls back for storage—less waste

Installation Workflow

PVC Mesh for Christmas Motif Lights installs in five short steps: measure, cut, pre-roll, fix, and check.

- Check dimensions and mark corners and stress points

- Cut mesh to 10–200 mm widths

- Pre-roll based on mesh direction

- Fix with clips or ties along the frame (add more at corners for smooth curves)

- Check for color differences and light spots

Tools: Use a cutting table with markings and a winding clamp with adjustable tension. Follow “main sections before details” to reduce rework.

Cold Weather Tip: Move material indoors or into a vehicle pre-warming area first. This improves flexibility.

Flame-Retardant Verification: Check label and certificate on delivery. Run a sample flame test if needed.

Quality & Testing

PVC Mesh for Christmas Motif Lights passes UV, tear, and −40°C bend tests with third-party options.

- UV aging: Accelerated test for color and tensile retention (ASTM G155)

- Low-temp bending: Flexibility verified at −40°C (ASTM D746)

- Tear & tensile strength: Ensures wrap durability (ASTM D624, D638)

- Colorfastness: Resists rain and cleaning effects

- Water resistance: Surface protection against seasonal moisture

Ordering & Logistics

PVC Mesh for Christmas Motif Lights ships in 10/50/100 m rolls with OEM/ODM support.

Standard Packaging: 1×10 m/box (can prepare 50–100 m large rolls per project)

Lead Time:

- Stock colors: Samples ship quickly

- Custom colors/mesh sizes: Engineers confirm schedule in quote

Delivery Terms: We support various trade terms and shipping plans. Works with your general or subcontractors.

After-Sales: Peak season stocking and fast replenishment. Clear material numbers for ERP tracking. Engineering drawings and install guides included for next year’s reuse.

Product Specifications

PVC Mesh for Christmas Motif Lights — typical specs below; custom sizes on request.

| Mesh Size | Best For | Reason |

|---|---|---|

| 2–4 mm | Complex curves, tight corners | More flexible, smoother finish |

| 5–7 mm | Standard motif frames | Balanced strength and flexibility |

| 8–10 mm | Straight rooflines, low wind | Higher stability, faster install |

| Parameter | Value |

|---|---|

| Material | Soft PVC (Eco-friendly PVC / RoHS available) |

| Mesh Aperture | 2–10 mm (3 mm typical) |

| Thickness | 0.2–1.0 mm (select by strength needs) |

| Width | 10–200 mm (cut as needed) |

| Length | 10 m / 50 m / 100 m roll (1×10 m/box standard) |

| Colors | Red, white, yellow, clear, blue, green, purple, pink (custom supported) |

| Performance | Anti-UV, anti-yellowing; FR/V0/V2 optional; cold-resistant −40°C; weatherproof |

| Compatibility | Eave/roofline lights, gutter, soffit/fascia, motif frames, neon flex/rope light |

| Installation | Clips / ties / wires; easy to bend, fits corners and irregular shapes |

| Supply | OEM/ODM; low MOQ; fast prototyping; includes tech drawings and install guides |

FAQ

Below are common questions on PVC Mesh for Christmas Motif Lights.

Q1: Why choose PVC mesh over tinsel or fabric strips?

A1:The mesh structure is lighter—less stress on large frames. Wrapping is quicker and more secure. The UV formula lasts longer outdoors.

Q2: Is it compatible with existing gutter lights and roofline systems?

A2:Yes. The material is flexible and easy to finish. It installs smoothly at eaves, corners, and gutters.

Q3: How do you control color consistency on a project site?

A3:Order the total quantity in one batch with the same batch number. Compare the color card before starting work. Keep a control card on site.

Q4: Can you provide flame-retardant grade and compliance documents?

A4:Yes. We offer FR/V0/V2 versions with RoHS/REACH declarations and test reports.

Q5: Is it suitable for long-term installations?

A5:It depends on the project. The material is weather-resistant and highly maintainable. It works well for seasonal reuse and semi-permanent setups.

Q6: What is the Minimum Order Quantity (MOQ)?

A6:We support low MOQ for trial orders and project pre-purchases. Contact us for specifics.

Q7: How do you prevent damage during shipping?

A7:We use thicker outer boxes and place rolls vertically. Anti-slip pallets are used for transport.

Ready to Order?

Ready to spec PVC Mesh for Christmas Motif Lights? Request a quote or download the datasheet.

Include project length, color, and whether flame retardancy is needed. We’ll arrange samples and shipping based on your timeline.

Need on-site guidance? Tell us your construction date. We’ll coordinate support.

Contact Us