Custom LED Christmas Light Strings: Complete Guide

Custom LED Christmas Light Strings let you design holiday displays with precise bulb placement and tailored lengths for your home’s architecture. These modular lighting systems—often called Custom LED Christmas Light Strings—use empty socket cords (stringers) paired with screw-in LED bulbs, eliminating excess wiring and awkward extension cords while giving you full control over spacing, colors, and coverage.

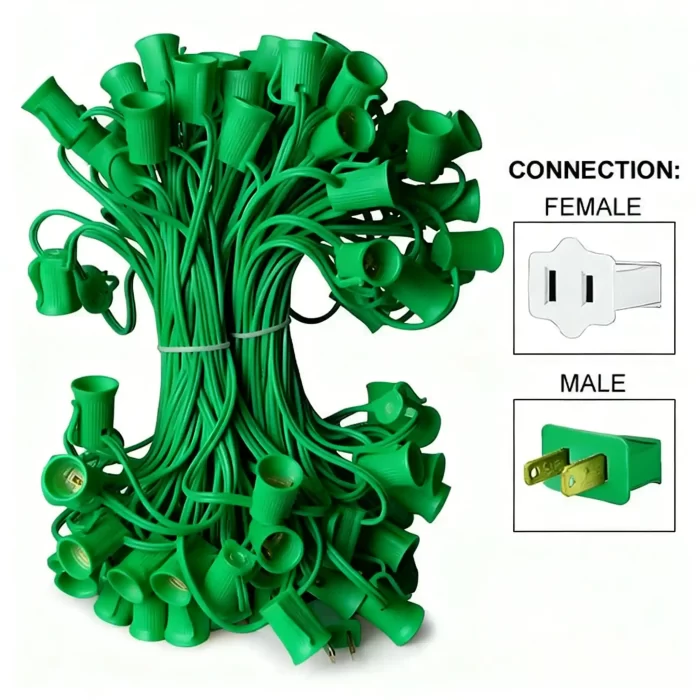

Empty Socket Cord & Plug Types | Custom LED Christmas Light Strings

Understanding Custom LED Christmas Light Strings

Custom LED Christmas Light Strings work fundamentally different from pre-assembled sets. Instead of purchasing fixed-length strings with permanently attached bulbs, you buy socket wire (also called stringers or spools) separately from the bulbs themselves. This approach mirrors how professional installers create seamless displays for commercial properties.

How Custom LED Christmas Light Strings Systems Work

A Custom LED Christmas Light Strings system has three main components. First, you select socket wire in your preferred length—available from 25-foot stringers up to 1000-foot commercial spools. Second, you choose socket spacing, typically ranging from 4 inches for dense coverage to 18 inches for architectural outlines. Third, you pick LED retrofit bulbs in any color combination you want, screwing them into the E12 (C7) or E17 (C9) sockets.

Socket Wire Spool (Stringer) | Custom LED Christmas Light Strings

Socket wire comes in SPT1 and SPT2 ratings, with SPT2 featuring thicker insulation rated for 10 amps compared to SPT1’s 7-amp capacity. For LED installations, SPT1 typically suffices due to lower power draw, while SPT2 suits incandescent bulbs or installations lasting beyond 90 days.

SPT-1 vs SPT-2 Insulation Thickness | Custom LED Christmas Light Strings

Christmas Tree vs. Custom LED Christmas Light Strings

Pre-wired LED Christmas tree string lights offer convenience but limited flexibility. A standard 50-bulb warm white strand works perfectly for indoor trees where standard lengths match your needs. Custom systems shine when your project demands specific measurements.

The choice depends on application scale. For a 6-foot indoor tree, pre-wired strings with 4-inch spacing provide adequate coverage at roughly 100 lights per foot of height. For rooflines with peaks, dormers, and varying angles, custom stringers eliminate the trailing wire that screams “amateur installation.”

Energy Efficiency of Custom LED Christmas Light Strings

LED lights use up to 90% less energy than incandescent bulbs, whether pre-wired or custom. A typical 5mm warm white LED draws just 0.096 watts per bulb. You can connect up to 216 watts end-to-end from a single outlet, allowing connections of 45 sets or more.

Types of Energy-Efficient Decorative Lights (Infographic)

This massive connectivity advantage means one outlet can power your entire roofline. Traditional incandescent strings max out at 5-10 connected sets before tripping breakers. Custom LED systems using C9 bulbs at 0.75 watts each let you install 288 bulbs on one circuit—enough for 2,400 feet at 12-inch spacing.

Custom LED Christmas Light Strings: White Spacing & Coverage

White string Christmas lights remain the most popular choice, but optimal spacing varies dramatically by application. Tree wrapping, roofline outlining, and branch lighting each require different approaches.

Calculating Christmas Tree Light String Spacing

For wrapping indoor Christmas trees, plan for a minimum of 100 lights per vertical foot with 4-inch bulb spacing for maximum lighting. A 7-foot tree needs approximately 700 lights for full coverage. If you prefer a lighter look, 6-inch spacing reduces the count to roughly 460 lights.

The formula for precise outdoor tree wrapping: (tree height in inches ÷ desired spacing in inches) × circumference in feet = total string length needed. For a 10-foot tree trunk with 3-foot circumference using 3-inch spacing, you’ll need 120 feet of lights just for the trunk.

Roofline and Architectural Spacing

For rooflines, Custom LED Christmas Light Strings at 12-inch spacing serve as the industry standard, though 9-inch or 6-inch spacing works for smaller structures needing more detail. C9 bulbs at 12-inch intervals create clean lines visible from the street, while closer spacing can overwhelm smaller homes or create a cluttered appearance.

Professional installers use this quick calculation: measure your roofline in feet, then multiply by 1.1 to account for corners and overlaps. A 150-foot roofline needs approximately 165 feet of socket wire at 12-inch spacing—exactly 165 C9 bulbs.

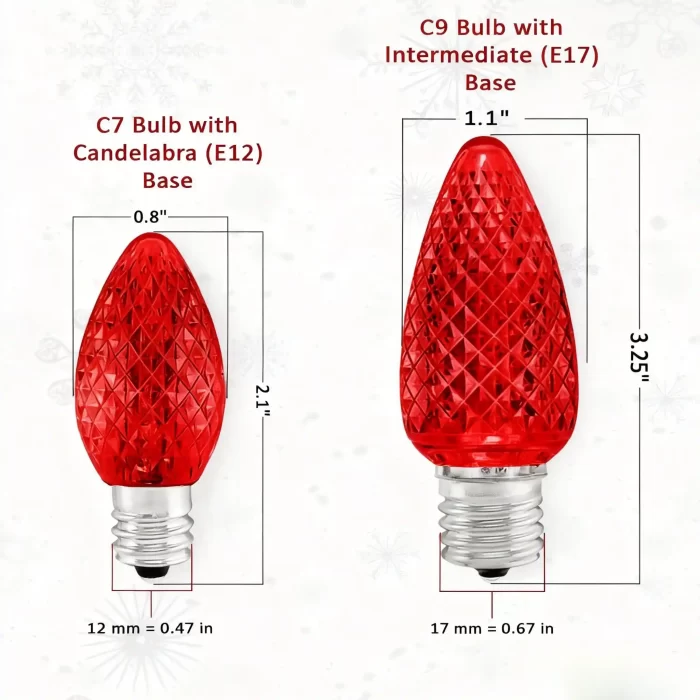

Custom LED Christmas Light Strings: C6/C7/C9 Bulb Selection

Choosing between C6, C7, and C9 bulbs determines your display’s visual impact and viewing distance effectiveness. Each size serves distinct purposes in professional-grade installations.

C6 LED String Lights

C6 bulbs measure approximately 0.75 inches in diameter and work beautifully for delicate applications. Their strawberry shape provides gentle illumination for shrubs, small trees, and indoor wreaths. The compact size disappears into branches during daylight, emerging only after sunset. Use C6 lights when you want illumination without the bulb becoming the focal point.

C7 LED Christmas String Lights

C7 bulbs have E12 bases and measure about 1.5 inches tall—the same base size as a nightlight. They’re perfect for medium-scale applications: pathway lighting, porch columns, window frames, and smaller residential rooflines. C7 bulbs at 0.5 watts each provide enough brightness for visibility without overwhelming architectural details.

C7 (E12) vs C9 (E17) Size Guide | Custom LED Christmas Light Strings

These lights excel at mid-range viewing distances of 20-50 feet. For townhomes, condos, or properties where neighbors are close, C7 bulbs create festive ambiance without light pollution concerns. C7 bulbs emit a softer, more intimate glow compared to their larger counterparts.

C9 LED Christmas String Lights

C9 bulbs reach roughly 2.25 inches tall with E17 intermediate bases, making them the statement piece of outdoor displays. Their size commands attention from 100+ feet away, perfect for main rooflines, driveway borders, and large trees. At 0.75 watts per LED bulb, they deliver impressive brightness while maintaining energy efficiency.

Use 6-inch spacing for roofline runs—it creates the ideal rhythm without making lights look overcrowded. This spacing suits most residential properties, though commercial buildings often expand to 12-15 inch intervals for cost efficiency.

Custom LED Christmas Light Strings: Custom Configurations

Custom configurations solve problems that standard strings can’t address. The ability to cut socket wire to precise lengths and add specialized connectors transforms challenging installations into clean, professional results.

Working With Zip Plugs and Custom Lengths

For Custom LED Christmas Light Strings, zip plugs feature a slide-off backing that lets you lay electrical cord inside, then presses the cord onto vampire teeth to create the connection. This tool-free installation takes seconds once you’ve cut your socket wire to the perfect length for your roofline segment.

The process: measure your run, cut the wire, strip away a small section of insulation, and snap the zip plug closed. Male plugs connect to outlets or extension cords. Female plugs receive the next section of lights. This modular approach means no wasted wire coiled behind downspouts or tucked under eaves.

For complex rooflines with multiple peaks, use split adapters. These accessories divide one line into 2, 3, 4, or even 8 directions, allowing continuous power flow without running separate extension cords to each section. The result: one outlet powers an entire elaborate display.

Socket Spacing Customization Options

Standard socket spacing includes 4, 6, 8, 12, 15, and 18 inches. Dense 4-inch spacing suits small decorative elements where you want maximum light with minimal visible wire. For wrapping branches, 6-inch or 8-inch spacing is recommended to allow space for wire to wrap tightly.

Wider 12-inch spacing excels for large-scale outlines where individual bulbs should read as distinct points of light rather than a continuous glow. The 15-18 inch options work for commercial buildings or situations where you’re highlighting architecture rather than flooding it with light.

You can also purchase bulk wire without sockets and add them yourself at any interval. This approach takes more time but grants absolute precision—perfect for unusual architectural features or artistic displays.

Smart Custom LED Christmas Light Strings

Modern smart Christmas string lights integrate app control, animation effects, and voice assistant compatibility. These systems represent the convergence of traditional string lights with IoT technology.

App-Controlled LED Options

Shine smart LED strings use 3D mapping technology—you frame lights with your smartphone camera and the app locates each LED’s position to create a virtual map. This enables effects that flow across your display in patterns impossible with standard controllers.

Types of Energy-Efficient Decorative Lights (Infographic)

The practical advantage goes beyond party tricks. You can save multiple configurations and switch between them instantly: warm white for dinner parties, animated multicolor for game nights, or synchronized patterns for holidays. Individually controllable LEDs allow you to design custom color schemes with 16 million color options.

Battery life on controller boxes varies, but most smart string systems draw 4-6 watts per 100 LEDs. The app connects via Bluetooth or WiFi, with WiFi providing better range for outdoor installations. Some systems like Shine G32 series offer music sync features that pulse lights to audio in real-time.

Commercial-Grade Custom LED Christmas Light Strings

Commercial installations demand durability beyond residential standards. Professional-grade lights use heavier gauge wire, superior bulb construction, and weatherproof connectors that survive months of outdoor exposure.

Watertight Coaxial Connector Systems

Commercial LED light strings with coaxial connectors prevent water intrusion between connections with threaded male and female ends that screw together. The watertight rubber washer ensures moisture can’t penetrate electrical connections, eliminating the corrosion that kills standard plug connections after one season.

This connector style can’t accidentally separate. Traditional end-to-end plugs pull apart from wind, weight, or accidental contact. Coaxial connectors require intentional unscrewing, making them essential for installations in high-wind areas or locations where lights hang unsupported.

Commercial strings feature thicker 20-gauge wire compared to the 22-gauge wire of standard string lights. This upgrade provides additional weather protection and allows more sets to connect end-to-end without voltage drop concerns.

IP Rating Considerations

IP44 ratings indicate lights can withstand rain and snow but shouldn’t be submerged. This suits 99% of residential and commercial applications. For installations near pools, fountains, or areas with standing water, upgrade to IP65 or IP67 ratings that offer complete dust protection and submersion resistance.

Climate matters too. Quality LED strings operate in temperatures from -4°F to 140°F, covering extreme conditions from Minnesota winters to Arizona summers. Cheaper imports often fail below 20°F as solder joints crack or plastic becomes brittle.

Custom LED Christmas Light Strings Installation Best Practices

Proper installation extends light lifespan and maintains appearance throughout the season. Professional techniques prevent common failures that shorten display life.

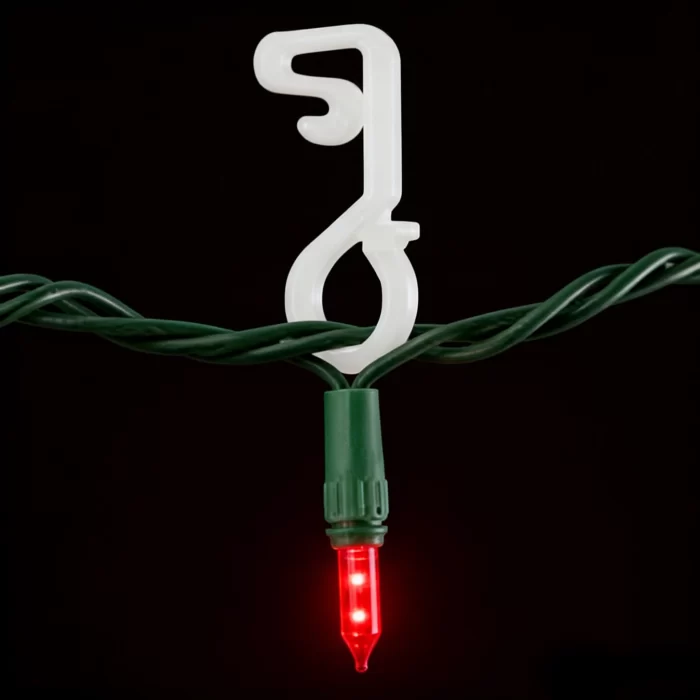

Wire Management Techniques

Always start by mapping your display on paper. Measure each section, calculate needed lengths, and add 10% for corners and overlaps. This planning prevents mid-installation store runs and ensures you have proper materials.

Use Christmas light clips designed for your mounting surface. Gutter clips, shingle tabs, and brick clips each serve specific purposes. Never staple through socket wire—the metal can pierce insulation and create shorts. Adhesive clips work for temporary installations on smooth surfaces.

Christmas Light Clip for Roofline/Gutter | Clean Install

When connecting multiple sections, create a service loop near plugs. This extra 6-12 inches of wire prevents stress on connections when thermal expansion contracts the wire in cold weather. Stress on connections causes 80% of mid-season failures.

Power Management and Circuits

Calculate total wattage before plugging in (see seasonal lighting safety tips from UL). LED efficiency means you’ll rarely approach circuit limits, but the math matters for safety. Premium LED strings allow you to safely connect up to 210 watts (typically more than 1000 feet of lights) on one plug.

Standard household circuits provide 15 amps at 120 volts, equaling 1800 watts of capacity. Load circuits to no more than 80% of capacity (1440 watts) to prevent nuisance tripping. A 1000-foot custom display at 0.096 watts per bulb draws just 96 watts total—you could run 15 such displays on one circuit.

White Custom LED Christmas Light Strings: Color Temperature (Kelvin)

White LEDs span a spectrum from warm amber tones to cool bluish whites. Understanding Kelvin ratings helps match your aesthetic preferences and coordinate with existing architecture.

Warm White vs. Cool White

Warm white LEDs (2700K-3000K) produce a soft, yellowish glow similar to traditional incandescent bulbs. This temperature suits traditional home styles, brick facades, and settings where you want cozy ambiance. The golden cast flatters warm-toned materials like wood and copper.

Cool white LEDs (5000K-6000K) emit a crisp, blue-tinged light that reads as “pure white.” This works beautifully with modern architecture, white or gray exteriors, and when you’re aiming for a winter ice palace aesthetic. Cool white stands out against snow and creates sharp contrast.

Pure white (4000K-4500K) splits the difference, providing neutral illumination that works with virtually any color scheme. This middle ground appeals to homeowners who want neither the amber warmth nor the blue coolness of the extremes.

Custom LED Christmas Light Strings: Maintenance & Storage

Proper maintenance extends LED string life from “good for a few years” to “usable for a decade.” The durability advantage of LEDs only materializes with correct handling.

Seasonal Storage Methods

Before storage, test every strand and replace burned-out bulbs. Mark problem sections with tape so you remember to repair them before next season. Coil strings loosely around cardboard or dedicated light reels—tight coiling stresses wire and connection points.

Store in climate-controlled spaces when possible. Attics reaching 140°F+ in summer can degrade wire insulation over time. Basement storage works perfectly, though ensure the area stays dry to prevent corrosion on metal components.

Label everything. Note the length, spacing, and location where each custom section installs. Next December, you’ll thank yourself when you can identify “front roofline left section, 47 feet” without untangling everything to measure.

Bulb Replacement and Repair

LED bulbs last 50,000+ hours theoretically, but socket corrosion or manufacturing defects cause earlier failures. If one bulb goes out, the rest stay lit, so you can replace failures at your convenience rather than troubleshooting dead sections.

Keep spare bulbs in your preferred colors. Match bulb style (smooth vs. faceted), color temperature, and brand when possible. Mixing manufacturers sometimes creates visible color variations as different LEDs age differently.

Clean bulb bases before screwing in replacements. A small wire brush removes corrosion that increases resistance and causes flickering. A tiny amount of dielectric grease on bases prevents future corrosion in outdoor installations.

Custom LED Christmas Light Strings: Cost vs. Pre-Made Sets

Initial investment for Custom LED Christmas Light Strings runs higher than pre-made strings, but the math shifts dramatically over multiple seasons and large installations.

Initial Investment Breakdown

A basic custom setup for a 200-foot roofline: 200 feet of socket wire at $0.80/foot ($160), 200 C9 LED bulbs at $0.95 each ($190), zip plugs and accessories ($30) totals $380. Equivalent pre-made strings would cost roughly $240 but require more outlets and extension cords (add $60), bringing the comparison to $380 vs. $300.

The custom advantage emerges in year two. When 15 bulbs fail in the pre-made system, you replace entire strings ($60-80). With custom, you replace 15 bulbs ($14). Over five seasons, the custom system costs $450 total while pre-made systems run $500-600 with repeated string replacements.

Large-Scale Project Savings

For 500+ foot installations, custom systems become dramatically cheaper. Bulk 1000-foot spools cost $0.50-0.60 per foot compared to $0.80 for smaller quantities. Professional-grade LED bulbs purchased by the case drop below $0.75 each. A 1000-foot commercial project costs $1,600-1,800 custom-built versus $2,500-3,000 using premium pre-made strings.

Labor efficiency matters too. Cutting socket wire to exact lengths eliminates the time spent managing excess wire and hiding it aesthetically. Professional installers report 20-30% faster installation with custom systems on complex rooflines.

Frequently Asked Questions

Can I mix different bulb sizes on the same socket wire?

No—C7 and C9 bulbs require different socket sizes. C7 bulbs use E12 candelabra bases while C9 bulbs need E17 intermediate bases. Socket wire comes designed for one base size. However, you can absolutely mix colors and styles within the same base size.

How long do LED Christmas string lights last?

Quality LED bulbs last 50,000 hours in theory, translating to 16+ years at 8 hours daily for 90 days per season. Real-world lifespan averages 10-12 years with proper storage. Socket wire lasts even longer—20+ years isn’t uncommon with professional-grade materials.

What’s the maximum length I can connect LED strings?

This depends on bulb wattage and wire gauge. Premium 5mm LED sets allow connections up to 1000+ feet on one outlet. C9 LED lights typically max out around 800-1000 feet. Always check manufacturer specifications as connecting beyond limits causes voltage drop that dims distant bulbs and overheats plugs.

Do I need special tools to create custom light strings?

For basic installations using pre-socketed wire and zip plugs, you need only wire cutters. No stripping or electrical work required—the vampire teeth design pierces insulation automatically. Installing individual sockets on bulk wire requires a socket punch tool and wire strippers, adding complexity but maximum customization.