China Meteor Xmas Lights: The Ultimate Outdoor Display for Holiday Magic

China Meteor Xmas Lights are LED tube lights that create cascading rainfall or meteor shower effects, manufactured primarily in Guangdong and Zhejiang provinces. These animated displays use SMD2835 LED chips arranged in transparent PC tubes, typically ranging from 12 to 36 inches, with each LED lighting sequentially to simulate falling stars or snow.For buyers comparing options, China Meteor Xmas Lights stand out for scalable production, consistent specs, and export-ready compliance documentation.

China Meteor Xmas Lights outdoor meteor shower display

Why China Dominates the Meteor Shower Xmas Lights Market

Chinese manufacturers produce 925 million units of Christmas tree lights annually(The data is based on industry estimates), with meteor shower lights representing a fast-growing segment. The concentration of production in cities like Shenzhen, Guangzhou, and Yiwu creates economies of scale that reduce manufacturing costs by 60-75% compared to Western production.

Manufacturing efficiency stems from three factors. First, vertical integration allows factories to control everything from LED chip production to final assembly. Second, specialized industrial clusters in Guangdong province house component suppliers, assembly facilities, and testing labs within a 50-mile radius. Third, automated SMD LED placement machines can process 720 LED chips per tube in under 90 seconds.

Chinese manufacturers produce Christmas lights at $0.15-0.30 per strand compared to $0.80-1.20 from other countries, enabling retailers to offer competitive pricing while maintaining healthy margins. This cost advantage doesn’t compromise quality—major Chinese factories hold CE, UL, CUL, REACH, and ROHS certifications, meeting or exceeding international safety standards.

Technical Specifications That Define Quality China Meteor Xmas Lights

LED Chip Quality and Brightness

Premium china meteor xmas lights use quality SMD2835 chips typically output a wide lumen range depending on bin and drive current. Ask suppliers for IES/LM-80/photometric reports or the LED datasheet for the exact lumen-per-chip figures. These chips provide 360-degree illumination visibility, important for outdoor displays where viewing angles vary. Lower-quality alternatives use 3528 or 5050 chips that produce uneven light distribution and shorter lifespans.

SMD2835 LED meteor tube lights close-up

Tube configurations typically range from 8 to 24 tubes per set, with each tube containing 18 to 48 LEDs depending on length. A standard 12-inch tube with 24 LEDs draws only 1.68W total, while delivering brightness comparable to 15W incandescent bulbs. The double-sided LED patch design ensures consistent illumination from all viewing angles.

Waterproof Construction and Durability

IP65-rated meteor lights can withstand heavy rain, snow, and temperatures from -20°C to 50°C (-4°F to 122°F). The transparent PC (polycarbonate) tube material resists UV degradation, yellowing, and impact damage. Quality tubes use a spiral internal design that enhances light refraction while maintaining structural integrity.

Connection systems vary by manufacturer. Professional-grade sets use threaded coaxial connectors that prevent accidental disconnection in wind or when installed at heights. Consumer-grade products may use simpler male-female plug connections. Up to 200 tubes can be connected on one power cord in commercial applications, though residential use typically connects 3-5 sets for optimal performance.

Voltage Safety and Certifications

Most meteor shower xmas lights operate on 7V or 12V DC after conversion from standard 110V-240V AC input. The 7V safe voltage is lower than human body safe voltage, reducing shock risk during installation or if wire damage occurs. UL-certified transformers include short-circuit protection and overload cutoff mechanisms.

Look for these certifications when sourcing from China: UL (North America), CE (Europe), SAA (Australia), RoHS (environmental compliance), and IP65 (water resistance). Factories with ISO9001 quality management systems demonstrate consistent production standards.

Selecting the Right China Meteor Xmas Lights for Your Display

Tube Length Considerations

Where to use meteor xmas lights: indoor vs outdoor

The tube length determines visual impact and installation locations:

12-inch (30cm) tubes work well for eave installations, mimicking icicles hanging from rooflines. The compact size suits residential front porches and smaller trees. Typical specifications include 18-24 LEDs per tube with 8-10 tubes per set, covering 20-30 feet of horizontal space with proper spacing.

16-inch (40cm) tubes offer a middle ground for versatility. They create noticeable motion without overwhelming smaller yards, suitable for medium-sized trees and patio structures. Expect 28-36 LEDs per tube and slightly wider spacing requirements.

24-inch (50cm) tubes deliver dramatic cascading effects ideal for tall trees and commercial installations. The extended length creates more prominent “falling” animation, though installation requires more vertical clearance. Professional displays often use these for street tree decorations and large building facades.

36-inch (80cm) tubes serve specialized applications like towering evergreens and multi-story buildings. The extended animation sequence creates mesmerizing displays but demands careful structural planning to prevent tube swaying in wind.

Color Options and Visual Effects

White meteor xmas lights dominate residential use, split between warm white (2700-3200K) for traditional ambiance and cool white (6000-6500K) for crisp, contemporary looks. Blue creates winter wonderland themes, particularly effective against snow or light-colored surfaces. Red and green dual-color sets satisfy those wanting traditional Christmas colors with animated motion.

Multi-color RGB sets use independent LED chips for each color, allowing varied display modes. Some addressable versions support DMX control for synchronized light shows, though these typically cost 40-60% more than single-color options. For most residential applications, single-color provides sufficient visual impact without programming complexity.

RGB multicolor meteor shower lights

The cascading speed affects perceived motion. Quality controllers create random delay patterns between tubes, preventing the synchronized “too perfect” look that seems artificial. Each tube typically completes a full cascade in 2-3 seconds, with 0.5-1.5 second delays between tube activations.

Power Requirements and Connectivity

Calculate total wattage before purchasing. An 8-tube set with 12-inch tubes (24 LEDs each) draws approximately 14W total. Four connected sets would require 56W, well within the 80-100W capacity of standard UL transformers. Exceeding transformer capacity shortens lifespan and creates fire hazards.

AC meteor lights plug directly into outlets and work, but a maximum of 2-3 strings can be connected at a time. Plan your power source locations accordingly. Extension cords should be outdoor-rated 14 or 12 AWG for lengths over 50 feet, and keep transformers sheltered from direct water exposure despite weatherproof ratings.

Installation Strategies for Maximum Impact

Tree Installations

Distribute tubes evenly around the tree canopy at varying heights to create depth. For a 10-foot tree, place tubes at 3, 5, and 7-foot levels, alternating positions around the circumference. This three-dimensional arrangement prevents flat appearance when viewed from different angles.

Secure tubes to branches using the built-in hooks or zip ties, ensuring tubes hang vertically without obstructions below. The falling light effect requires clear space for the full tube length plus 12-18 inches. Test the display before final securing—LED sequences may need adjusting based on actual viewing positions.

Large trees benefit from multiple entry points for power connections. Rather than daisy-chaining all sets from one cord, create 2-3 separate circuits that converge at hidden connection points within the canopy. This approach simplifies troubleshooting and prevents total display failure if one circuit issues occur.

Roofline and Eave Applications

Space tubes 16-24 inches apart along eaves for icicle-effect displays. Closer spacing creates denser light walls but requires more sets and careful cable management. Use gutter clips or adhesive hooks rated for outdoor use—suction cups fail in cold temperatures.

Maintain consistent tube height positioning. Even minor variations (2-3 inches) become obvious when multiple tubes cascade simultaneously. Measure and mark positions before installation, especially on multi-story buildings where access is limited.

Roofline and tree meteor shower lights examples

Consider viewing angles from streets and driveways. Meteor lights create the most impact when viewers see the full tube length. Front-facing installations work better than side profiles, though corner positions can create impressive converging effects.

Commercial and Large-Scale Displays

Professional installations of meteor shower xmas lights often incorporate DMX controllers for synchronized sequences across hundreds of tubes. This technology supports timed changes, color transitions, and music synchronization, though it requires specialized programming knowledge.

These LED Meteor Shower Lights carry up to 720pcs 2835 SMD LED in one set with 10 tubes per set, delivering high brightness at ample coverage. For shopping centers and public spaces, specify commercial-grade sets with reinforced mounting hardware and extended warranties.

Power distribution becomes critical in large installations. Calculate amp draw for each circuit and never exceed 80% of breaker capacity. Hire licensed electricians for permanent installations requiring junction boxes or new outlet installations.

Sourcing Quality China Meteor Xmas Lights: Factory Evaluation

Manufacturer Verification Process

Direct factory sourcing requires diligence. Start with B2B platforms like Alibaba and Made-in-China, filtering for Gold Suppliers with Trade Assurance and 5+ years of verified transactions. Request business licenses, ISO certifications, and recent audit reports from SGS or Bureau Veritas.

Video factory tours reveal production capabilities and quality control processes. Look for automated SMD placement equipment, aging test chambers running 72-hour burn-in cycles, and waterproof testing stations. Manual assembly lines can produce quality products but lack consistency at scale.

Sample orders should test multiple aspects: LED brightness uniformity, color accuracy, waterproof sealing integrity, and connector durability. Order from 3-4 manufacturers simultaneously for direct comparison. Pay attention to packaging quality—it indicates care levels that extend to product quality.

Key Questions for Suppliers

Ask about LED chip brands and specifications. Reputable manufacturers use chips from Epistar, Sanan, or similar tier-1 suppliers. Request photometric test reports showing actual lumen output and color rendering index (CRI). Values below 70 CRI produce washed-out colors.

Inquire about warranty terms and defect rates. Quality factories offer 1-2 year warranties and maintain defect rates below 0.5%. Ask how warranty claims process—slow or complex procedures indicate poor after-sales support.

Minimum order quantities (MOQ) vary from 100 to 1,000 sets depending on customization requirements. Standard configurations have lower MOQs than custom colors or lengths. Negotiate payment terms carefully—never pay 100% upfront. Standard terms are 30% deposit, 70% before shipping, with LC available for large orders.

Regional Manufacturing Specializations

Yiwu in Zhejiang province specializes in decorations and small gifts, while Guangdong focuses on lighting and electronic products. For meteor xmas lights, Guangdong factories generally offer superior technical capabilities due to the region’s electronics manufacturing ecosystem.

Shenzhen and Dongguan within Guangdong province house the most advanced LED production facilities. These cities benefit from proximity to component suppliers and skilled electronics assembly workers. Taizhou in Zhejiang province also produces Christmas lights, often at slightly lower prices but with less vertical integration.

Consider logistics when selecting regions. Guangdong’s proximity to major ports (Shenzhen, Guangzhou) reduces inland transportation costs and simplifies export procedures. Some U.S. importers prefer Ningbo port access from Zhejiang suppliers despite slightly longer ocean transit times.

Market Trends Shaping China Meteor Xmas Lights in 2024-2025

The global Christmas lights market reached $8.09 billion in 2024, with expected growth of 3.75% CAGR through 2033. Meteor shower lights represent a growing subset as consumers seek animated effects beyond static string lights.

Solar-powered versions emerged in 2024, addressing outdoor power access challenges. These systems use amorphous silicon panels charging 3000mAh lithium batteries, providing 6-8 hours of operation after full charging. However, solar options cost 30-50% more and may underperform in winter’s reduced daylight, limiting mainstream adoption.

IP65 solar meteor xmas lights for outdoors

Smart home integration represents another trend. App-controlled meteor lights support color changes, timing schedules, and brightness adjustment via Wi-Fi connectivity. While appealing to tech-savvy consumers, the added electronics reduce weatherproofing reliability and typically aren’t worth the premium for temporary seasonal displays.

The low cost of raw materials and labor enables large-scale production and export of these products, though recent tariff adjustments impact profit margins. Import duties can change based on HS code and policy updates, so build a pricing buffer and verify rates with your customs broker before locking margins. As a result, many importers are accelerating supply-chain diversification rather than relying solely on China.

Installation Safety and Maintenance

Electrical Safety Protocols

Always use GFCI-protected outdoor outlets for meteor shower xmas lights. These circuits detect ground faults and shut off power within milliseconds, preventing shock hazards in damp conditions. Test GFCI function monthly by pressing the test button—if the outlet doesn’t shut off, replace it before using for Christmas lights.

Keep transformer plugs elevated above ground level and shielded from direct precipitation despite weatherproof ratings. Water ingress into plug connections causes corrosion and creates shock risks. Use weatherproof outlet covers that accommodate plugs while closed.

Inspect all connections before each use. Look for frayed wires, cracked insulation, or corroded contacts. Replace damaged components rather than attempting repairs with electrical tape—proper insulation matters for safety. Never connect damaged sets hoping they’ll still work.

Storage for Longevity

Proper storage extends meteor light lifespan to 5-7 seasons. Wind tubes loosely around cardboard tubes or storage reels, avoiding tight coils that stress LED solder joints. Place tubes in sealed plastic bins with silica gel packets to control moisture.

Store in temperature-controlled spaces when possible. Garage storage works if protected from extreme heat—temperatures above 50°C (122°F) degrade plastic components and LED phosphor coatings. Attic storage risks heat damage in summer months.

Label storage containers with set specifications (color, tube length, number of tubes) and last inspection date. This organization simplifies planning for next season and helps track which sets may need replacement.

Comparing China Meteor Xmas Lights to Alternatives

Traditional icicle lights cost less initially ($15-25 per 150-light set) but lack the animated motion that makes meteor lights distinctive. Static displays require more lights to create similar visual interest, potentially negating the cost advantage.

Projection lights create large-scale effects with single units but suffer from limitations. They require specific mounting angles, don’t work well in bright ambient lighting, and wash out in fog or precipitation. Meteor lights maintain visibility in varied weather conditions and create genuine three-dimensional displays.

C9 or C7 bulb strings offer classic aesthetics and easier individual bulb replacement but consume 7-10x more energy than LED meteor options. For large displays running 6-8 hours nightly through the season, this energy difference becomes significant—a 50-tube meteor display draws 60-80W versus 500-700W for equivalent incandescent coverage.

Troubleshooting Common Issues

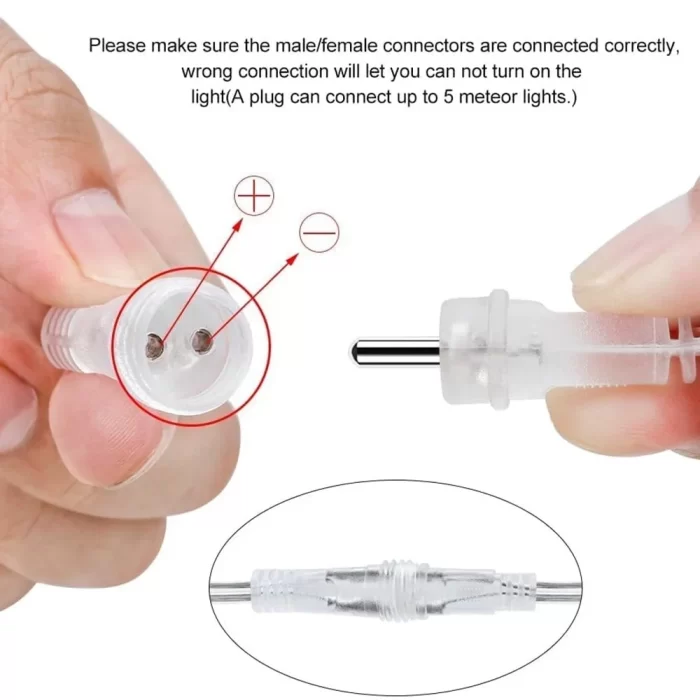

Tubes not lighting: Verify positive/negative connector alignment—reversed polarity prevents operation. Many sets include grooved connectors to prevent incorrect connections, but older models may not. Disconnect and reconnect with opposite orientation.

Connector polarity guide for meteor lights

Partial tube operation: Individual LEDs failing indicates manufacturing defects or shipping damage. Quality manufacturers wire LEDs in parallel circuits so single LED failure doesn’t affect others, though this costs more than series wiring. Contact suppliers about replacements if failures occur in first season.

Inconsistent cascading speed: This often indicates voltage drop from excessive sets connected in series. Reduce the number of connected sets or add a second power circuit. Voltage drop causes LEDs at the end of chains to operate below specification, creating erratic behavior.

Water intrusion in tubes: Check end caps for proper sealing. Some designs use silicone gaskets that may shift during shipping. Ensure caps press firmly against tube ends and consider adding a thin bead of clear silicone if gaps appear.

Environmental Considerations

LED meteor xmas lights consume 85-90% less energy than incandescent equivalents, reducing both electricity costs and carbon footprint. A typical residential display using 200 LEDs across multiple sets draws 15-20W total, compared to 150-200W for similar incandescent coverage.

PC tube material is recyclable through specialized facilities, though few curbside programs accept it. Some manufacturers implement takeback programs for end-of-life products, particularly in European markets where extended producer responsibility regulations apply.

The electronic components (LEDs, circuit boards, transformers) contain trace amounts of rare earth elements and should be recycled through e-waste programs rather than general trash. Many municipalities offer seasonal electronics recycling events coinciding with post-holiday disposal periods.

Packaging typically uses cardboard and minimal plastic, though foam inserts protect tubes during shipping. Consider requesting reduced packaging for large orders to minimize waste, though this may increase damage risk during transit.

Frequently Asked Questions

How long do China Meteor Xmas Lights last?

Quality sets using SMD2835 LEDs typically last 30,000-50,000 hours of operation, equivalent to 15-25 years at 6 hours daily use over 8-week holiday seasons. The transformer and wiring often fail before LEDs do, making purchasing from manufacturers offering component-level warranties valuable. Expect 3-5 season lifespan for budget options using lower-grade components.

Can meteor lights be left on continuously?

While technically capable of 24/7 operation, continuous use accelerates LED degradation and unnecessarily consumes electricity. Set timers for 6-8 hour windows during peak viewing hours. This approach extends lifespan and reduces the $2-4 monthly electricity cost per standard display to under $1.

Are meteor lights safe for outdoor trees?

Yes, when properly installed. The 7V or 12V DC operation after transformer conversion eliminates high-voltage risks, and quality sets meet IP65 water resistance standards. Ensure transformers remain protected and avoid wrapping wires tightly around branches—allow slack for tree movement in wind.

What’s the difference between meteor lights and falling rain lights?

These terms describe the same product type. “Meteor shower lights” emphasizes the shooting star effect, while “falling rain lights” highlights the dripping water appearance. Both use identical LED tube technology with sequential illumination patterns. Some manufacturers reserve “meteor” for longer tubes (24-36 inches) and “rain” for shorter versions (8-12 inches), but no industry standard exists for this distinction.