A Buyer’s Guide to Sourcing Large 3D Motif Light Displays from China

✯Value Proposition): Sourcing large 3D motif light displays from unverified suppliers often causes costly delays and quality failures. This definitive 2025 guide—built for municipal, mall, and theme-park buyers sourcing 3d motif lights at scale—provides a step-by-step framework for verified motif light supplier procurement, turning a complex process into a predictable success.

Large outdoor LED light sculpture in a city park at night

What You’ll Achieve:

- ✅ Verify elite manufacturers with a 4+1 vetting process.

- ✅ Ensure quality with a 35-point downloadable factory audit checklist.

- ✅ Import confidently with compliance playbooks for global markets.

- ✅ Prove ROI with real-world cases and verifiable data.

Get the 35-Point Checklist Used by 500+ Procurement Managers ⚡

- Last updated: Nov 11, 2025 | By Adrian Liang, 15+ Years in LED Lighting Manufacturing & Sourcing.

What Are 3D Motif Lights? Understanding the Core Components

3D motif lights—also called LED sculpture lights or festive motif lighting—are engineered, three-dimensional displays built on structural metal frames wrapped with weather-resistant LED modules. Controlled via DMX512 (and often Art-Net/sACN), they deliver static to fully synchronized shows for municipal, retail, and theme-park venues. Professional builds specify ingress protection (typically IP66/67), driver and surge protection, and structural design for local wind loads. Sizes range from small indoor accents to landmark-scale outdoor installations over 50 ft (≈15 m), where engineering sign-off, installation method, and maintenance access are part of the procurement scope.

Outdoor LED Christmas light sculpture with visitors for scale

Procurement Classification Matrix:

| Type | Height Range | Ingress Protection | Control Method | Mounting Method |

|---|---|---|---|---|

| Small Motif | 2-6 ft (0.6-1.8 m) | IP65 | Static / Simple Chase | Base Plate / Stand |

| Medium Motif | 6-15 ft (1.8-4.5 m) | IP66 / IP67 | DMX Basic | Anchor Bolts |

| Large Motif | 15-30 ft (4.5-9 m) | IP67 | DMX / Art-Net | Engineered Concrete Base |

| Giant Motif | 30-50+ ft (9-15+ m) | IP67 | Art-Net / sACN | Engineered Foundation |

Expert Insight): Professional-grade motifs must use structural materials like 6061-T6 aluminum or hot-dip galvanized steel. Unprotected carbon steel is not recommended for permanent outdoor displays due to corrosion risks. For installations in North America, structures must be engineered per ASCE 7-16 standards and comply with local NEC/CEC inspection requirements (AHJ). In Europe, the IEN 60598 family of standards is the primary reference.

Comparison image of 6061-T6 aluminum and rusted carbon steel.

The Strategic Advantage: Why Source Large 3D Motif Displays from China?

The decision to source from China provides strategic access to the world’s most advanced and scalable lighting supply chain.

| Dimension | China Sourcing | Local Sourcing |

|---|---|---|

| Unit Cost | 30-50% Lower | Higher |

| Custom Lead Time | 4-6 Weeks | 8-12 Weeks (due to sub-supplier reliance) |

| MOQ Flexibility | High (Scalable Production) | Often Rigid & High |

| Technology Options | Extensive (DMX, Art-Net, sACN) | Limited |

| Compliance Path | Deep experience with UL/CE/CSA | Often requires Field Evaluation |

| Spares & SLA | 2-5% Recommended; ≤24-48h Response | Varies, Potentially Faster but Costlier |

| R&D Capability | High (Integrated supply chain) | Varies by supplier |

| Scalability | High (Large production capacity) | Limited |

E-E-A-T Evidence: Across 200+ projects, our clients typically see 40–60% TCO savings. This cost analysis is key to successful import LED motif lights projects, though actual results depend on size, show-control, and compliance scope.

The 4+1 Step Process to Find & Vet a Verified Motif Light Supplier

Phase 1: Screening & Documentation

● Step 1: Initial Screening Build a long list of 10-20 potential suppliers from B2B platforms, trade shows, and referrals. Focus on those specializing in large-scale, project-based lighting.

● Step 2: Documentation Review (Follow this order):

①Business License: Confirms they are a “Manufacturer”.

②ISO 9001: Validates process management.

③UL Certificate: Search the file number on the official UL Product iQ database to ensure the supplier is the listed holder.

④CE DoC: Cross-reference the model number on the Declaration of Conformity with the technical file directory.

⑤Test Reports: Ensure they are from labs accredited by CNAS/ILAC-MRA.

Phase 2: Technical & Final Vetting

● Step 3: Technical Expertise Assessment (Ask these questions):

⒈Can you guarantee ≤3 SDCM for LED binning in the contract?

⒉What is your driver’s input voltage range (100–277V or 347–480V options)?

⒊Can you provide grounding/bonding details for GFCI compatibility?

⒋Is Surge Protection (SPD) of ≥4–10 kV standard for your outdoor products?

⒌Can you provide compatibility lists and wiring diagrams for DMX/Art-Net/sACN?

● Step 4: Due Diligence & Final Vetting For your top 3 candidates, conduct video factory tours, check references, and analyze their project portfolio for scale and complexity.

✦ Step 5: Pilot Sample Run Commission a scaled-down sample from your chosen supplier to physically test build quality, packaging, and system integration before committing to a large order.

● Red Flags: Vague answers on DMX addressing, refusal to provide serial number traceability samples, or claiming “UL compliance” with only a component-level (UL Recognized) certificate.

The Ultimate Factory Audit Checklist (Your Downloadable Scorecard)

Our 35-point checklist uses a 0-5 scoring system (qualifying score: ≥3.5). However, any score below 3 on a critical must-pass item is an automatic disqualification. This audit is the ultimate test of a supplier’s trustworthiness.

● Critical Must-Pass Items:

○ Aging Test: ≥24h baseline; 48-72h recommended for high-power/pixel-dense systems.

□ Hi-Pot / Insulation Test: Confirms electrical safety.

○ IP Rating Test: Verifiable in-house or third-party reports.

□ Traceability: A robust system linking serial numbers to production records (BOM, ECN).

✦ Materials & Anti-Corrosion: For harsh environments (C3/C4), verify the use of a hot-dip galvanization plus powder coating system.

● Visual Evidence: Demand photographic proof of the packaging, plus screenshots of aging test records for your specific production units.

Every critical must-pass item on this scorecard directly addresses a failure point. To fully understand why these checks are mandatory, 【review the 7 Most Common Causes of 3D LED Motif Light Failures】and see how poor sourcing leads to structural decay, electrical failure, and liability.

How to Import: Contracts, Compliance & Logistics

Incoterms Responsibility Matrix:

| Responsibility | EXW | FOB | CIF | DDP |

|---|---|---|---|---|

| Packaging | Seller | Seller | Seller | Seller |

| Loading at Origin | Buyer | Seller | Seller | Seller |

| Main Transport | Buyer | Buyer | Seller | Seller |

| Insurance | Buyer | Buyer | Seller (Min.) | Seller |

| Customs Clearance | Buyer | Buyer | Buyer | Seller |

| Duties & Taxes | Buyer | Buyer | Buyer | Seller |

| Final Delivery | Buyer | Buyer | Buyer | Seller |

✦ Landed Cost Guidance: Budget 10-25% of the FOB value for shipping and port fees. Oversized crates or flat-rack shipping may exceed this; confirm early with your forwarder.

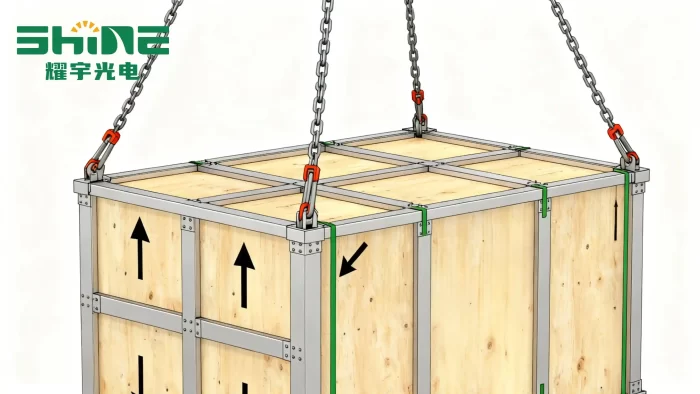

● Packaging Clause: Your contract must specify: center of gravity marks, designated lifting points, and anti-shock foam thickness. Always request photographic evidence of the packaging before the container leaves the factory.

The detailed planning for shipment, assembly, and off-season storage begins here, immediately after the contract is signed.

【Consult our Expanded FAQs: Shipping & Assembling Large-Scale 3D Motif Lights Internationally】for essential B2B answers on crating, final installation difficulty, and modular design.

Real-World Case Studies & ROI

● Case Study 1: Municipal Project (North America)

○ Background: A Canadian city needed a durable, iconic holiday display for a high-traffic plaza.

□ Challenge: The display had to withstand -40°C temperatures and high wind loads, requiring full UL/CSA compliance verified by the local Authority Having Jurisdiction (AHJ).

○ Solution: A custom 30-foot (≈9m) Moose, engineered with structural-grade aluminum and IP67 components.

□ Results & Verification:

⧫ KPI 1 (Energy Savings): 82% vs. the previous incandescent system.

✦ KPI 2 (Maintenance): 95% reduction in service calls in the first season.

⧫ KPI 3 (Footfall): +25% downtown traffic during the display period.

✦ Verification: Passed AHJ inspection on the first attempt; structural and foundation interface drawings were provided and approved.

● Case Study 2: Retail Mall (Asia)

○ Background: A premier Singaporean mall aimed to create an “Instagrammable” centerpiece to drive foot traffic during the competitive holiday season.

□ Challenge: The display needed to be visually dynamic, highly reliable for daily light shows, and integrate with the mall’s existing building management system.

○ Solution: A 20-foot (≈6m) animated 3D Christmas tree with fully programmable DMX RGB lighting, enabling synchronized daily light shows.

□ Results & Verification:

⧫ KPI 1 (Footfall): +34% increase during the campaign period vs. the prior year.

✦ KPI 2 (Social Engagement): Over 50,000 tagged photos and videos on Instagram, generating massive organic reach.

⧫ KPI 3 (Dwell Time): Average visitor dwell time in the central atrium increased by 15 minutes.

✦ Verification: System integration was validated via remote diagnostics; uptime was 99.9% over the 6-week campaign.

● Case Study 3: Theme Park (Middle East)

○ Background: A new theme park in the UAE required a monumental entrance archway that would function as a landmark day and night.

□ Challenge: The structure had to operate flawlessly in 120°F (49°C) summer heat and withstand frequent sandstorms, requiring a SASO-certified, IP67-rated solution with advanced thermal management.

○ Solution: A 45-foot (≈13.7m) archway built with enhanced heat sinks, sealed with industrial-grade silicone, and using components fully compliant with SASO and ESMA(Now for MoIAT) standards.

□ Results & Verification:

⧫ KPI 1 (Reliability): 0 critical failures reported in the first 18 months of continuous operation.

✦ KPI 2 (Operating Temp): Internal temperature sensors confirmed performance well within the safe operating range, even on the hottest days.

✦ KPI 3 (Guest Feedback): Mentioned in 40% of positive online reviews as a key park highlight.

⧫ Verification: Passed mandatory third-party pre-shipment inspection required for SASO certification.

Explore our complete portfolio of large-scale lighting projects.

Expanded FAQ (Frequently Asked Questions)

(This section is formatted with collapsible accordion menus for better UX)

🔍 Pre-Purchase & Vetting

✯Q1: How do I verify a supplier’s factory is real and not just a trading office?

A: Request a live, unedited video tour during their stated working hours. Ask them to show you specific production areas (like the aging test room) and have them write your company’s name on a whiteboard in real-time.

✯Q2: What’s the typical MOQ for custom 3D motif lights?

A: For large, unique, custom pieces (over 15 feet), the MOQ is almost always one unit. For smaller, repeatable designs, a supplier might ask for an MOQ of 10-50 pieces.

✯Q3: Can I visit the factory in person before placing an order?

A: Absolutely. Any reputable, verified manufacturer will welcome a factory visit. It’s the best way to conduct due diligence for a significant project.

✯Q4: What payment terms are standard in this industry?

A: The most common structure is a 30-50% deposit to begin production and the remaining 50-70% balance due after your final inspection but before shipping.

✯Q5: How can I customize the color of the LED lights?

A: You can specify RGB or RGBW LEDs for full-color control via DMX. For static colors, you can specify the exact color temperature (e.g., 2700K Warm White) or specific single colors (e.g., red, blue).

📋 Certification & Compliance

✯Q6: Is UL Listing really necessary, or is UL Recognized enough?

A: For a component like a power supply inside a larger system, UL Recognized may be acceptable. However, for a standalone, permanent installation in North America, the local electrical inspector (AHJ) will almost always require the entire, final product to be UL Listed.

✯Q7: Can a non-UL Listed motif be approved by a local inspector?

A: In some rare cases, an inspector may accept a one-time “Field Evaluation” by a Nationally Recognized Testing Laboratory (NRTL). However, this process is expensive, time-consuming, not guaranteed, and should be considered a last resort.

✯Q8: How do I verify a CE mark is authentic?

A: Ask for the full Declaration of Conformity (DoC) and the underlying technical test reports from an accredited lab. Verify that the product model number on the documents matches your order exactly.

✯Q9: What about compliance for the UK market after Brexit?

A: For the market in Great Britain (England, Scotland, Wales), the UKCA mark is now required. It largely follows the same technical principles as the CE mark but requires a separate declaration.

✯Q10: Do wireless controllers have special requirements?

A: Yes. Any device using radio frequencies must comply with local regulations, such as FCC Part 15 in the US and the RED (Radio Equipment Directive) in the EU.

🚢 Logistics & Import

✯Q11: What are the hidden costs when using FOB shipping terms?

A: FOB (Free On Board) means the seller’s responsibility ends once the goods are on the shipping vessel. You are responsible for all subsequent costs: ocean freight, insurance, destination port fees, customs clearance, duties/tariffs, and final inland delivery.

✯Q12: How do I handle voltage differences between countries?

A: This must be specified in the technical design phase. North America typically uses 120V/277V/347V, while Europe and other regions use 220-240V. Your supplier must use the correct power supplies for your target market.

✯Q13: How long does shipping from China typically take?

A: Ocean freight to North America usually takes 4-6 weeks, while to Europe it can take 5-7 weeks. This does not include production time or potential customs delays.

✯Q14: Should I buy my own cargo insurance?

A: Highly recommended. Even if your supplier provides basic insurance under CIF terms (which is often minimal), a separate, all-risks policy (like ICC-A) provides better protection against damage or loss.

🔧 After-Sales & Maintenance

✯Q15: What happens if a unit fails during the warranty period?

A: Your contract should clearly define the RMA (Return Merchandise Authorization) process. Typically, the manufacturer will ship replacement parts free of charge. Negotiate who covers the shipping costs for these parts.

✯Q16: Can I use IP65 fixtures in heavy snow regions?

A: While IP65 is water-resistant, we recommend IP67 for areas with heavy snow and freeze-thaw cycles. IP67 ensures better protection against water ingress from melting snow that can pool around seals.

✯Q17: How should we plan for maintenance access on giant displays?

A: This must be part of the initial design. Specify the need for internal access ladders, strategically placed service hatches, and the use of quick-connect waterproof connectors to allow for modular replacement of LED sections or power supplies.

✯Q18: What is the typical lifespan of outdoor 3D motif lights?

A: A professional-grade display using high-quality LEDs and drivers should have a lifespan of 50,000+ hours to L70 (meaning the light output will have degraded to 70% of its initial brightness). This translates to many years of seasonal or continuous use.

✯Q19: Can the displays be disassembled for seasonal storage?

A: Yes, many large motifs are designed in modular, bolt-together sections for easier transport, installation, and off-season storage. This should be a key requirement in your design brief.

Common Pitfalls in B2B Motif Light Procurement & How to Avoid Them

● Pitfall 1: Color Shift: Failing to specify LED binning standards, resulting in noticeable color differences between sections.

○ Avoidance: Mandate ≤3 MacAdam ellipse (SDCM) for color consistency in your contract and specify visual batch testing during the final inspection.

Color temperature comparison: 2400K—6200K (warm white → cool white)

● Pitfall 2: Voltage Mismatch: Overlooking North American commercial voltages like 277V or 347V, leading to incompatible power supplies.

□ Avoidance: Clearly define the required input voltage and electrical phase in your technical specifications and demand a corresponding wiring diagram.

● Pitfall 3: Inadequate Packaging: Accepting standard packaging for oversized, fragile items, leading to transit damage.

○ Avoidance: Contractually require steel-frame crating and photographic sign-off before shipment.

● Pitfall 4: Ignoring Wind Load: Purchasing a large outdoor display without a certified structural engineering report for your specific location.

□ Avoidance: Make the provision of a wind load calculation report, stamped by a certified engineer, a mandatory contractual deliverable.

● Pitfall 5: No Spare Parts Agreement: A critical power supply or LED module fails mid-season with no replacements on hand, causing unacceptable downtime.

○ Avoidance: Negotiate a 2-5% spare parts package (covering critical components like drivers, LEDs, and connectors) as part of the initial contract.

Conclusion: Your Partner for Successful Sourcing

Successfully sourcing verified 3D motif lights from China transcends finding the lowest price; it requires a strategic, risk-managed approach. By deploying a rigorous vetting process, demanding transparency, and defining every technical and logistical parameter in your contract, you can secure a reliable manufacturing partner. By treating B2B motif light procurement as a strategic partnership, you move beyond mere transaction and establish a resilient supply chain for your most iconic projects.

Ready to start your sourcing journey with confidence?

● -> Explore More Possibilities for LED Decorative Lights