Product Overview

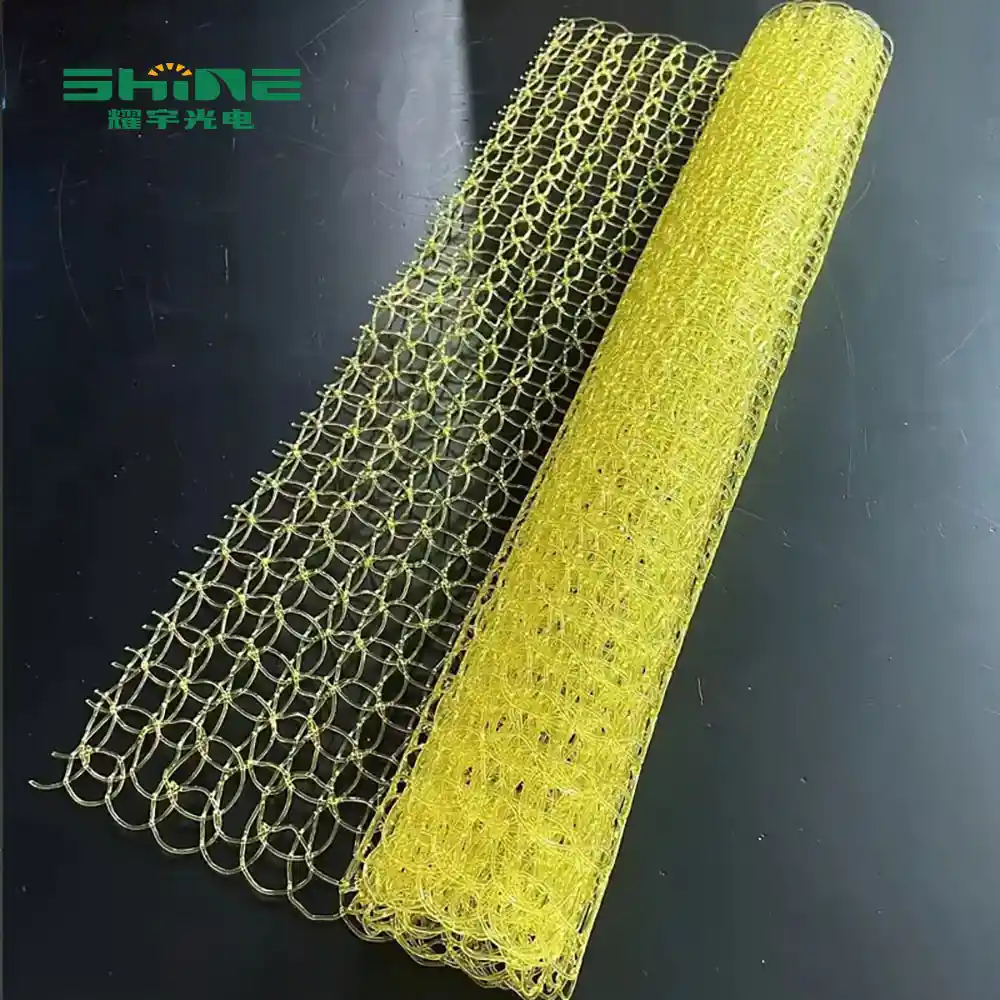

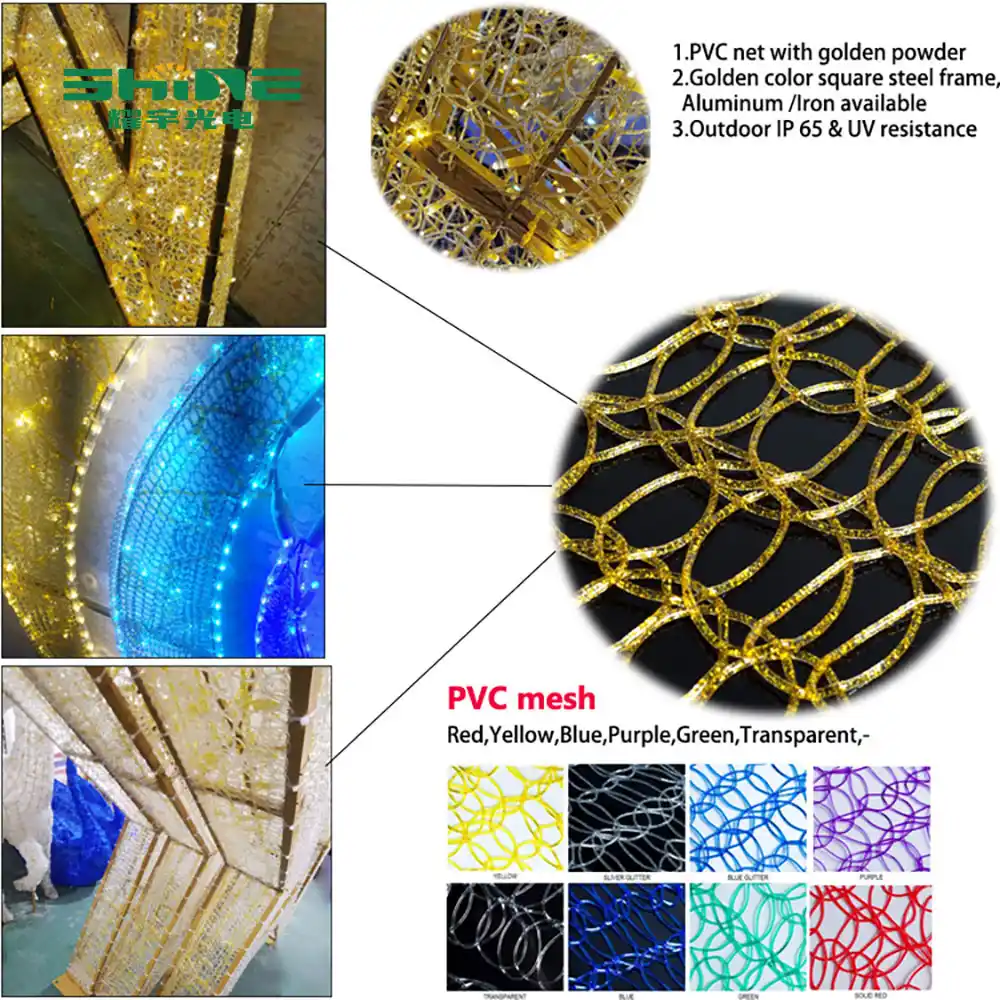

- This pvc mesh carpet is an outdoor-ready base material for standardized Christmas motif lighting in plazas, theme hotels, and commercial complexes. It combines a regular 6 cm aperture for predictable module layout with ~92% light transmission for consistent visual output, so engineering teams can design once and replicate across sites with confidence.

- Because it remains flexible, crews route LED modules neatly and secure them with mechanical fixing, which shortens work-at-height time and reduces onsite variability. Meanwhile, the −20 °C to 70 °C operating range and IP65 ingress protection support long seasonal duty in real weather.

- To match different visual intents, you can choose frosted diffusion for soft ambience or a sequin finish for high-sparkle façades without raising drive current. Furthermore, cartonized 1×10 m rolls simplify transport, stocking, and last-minute reconfiguration.

Key Specs at a Glance

-

Base material: UV-resistant pvc mesh carpet with ~92% light transmission.

-

Aperture geometry: regular 6 cm; spacing can be encrypted toward ~3 cm in high-detail zones.

-

Format: 1×10 m per carton; optional 1×5 m for tighter spaces.

-

Protection & climate: IP65; −20 °C to 70 °C operation.

-

Surface options: frosted or sequin double coating.

-

Electrical context: supports dense LED modules; DC 6 V / 12 V / 24 V—confirm per project BOM.

-

Typical coverage: multi-roll splicing to 50 m²+ for floor mats or façades.

Why B2B Teams Choose This pvc mesh (Value for Contractors & Owners)

-

Standardize layouts across cities: a single 6 cm grid becomes the common denominator for snowflakes, elk, and custom logos, cutting drawing time and field improvisation.

-

Install faster with fewer surprises: flexible routing plus mechanical fixing reduces lift hours, which often translates to 20%+ labor savings in typical deployments.

-

Run reliably outdoors: IP65 and −20 °C~70 °C stability limit mid-season call-outs, improving uptime during peak holiday windows.

-

Tune aesthetics without re-engineering: pick frosted for glare-sensitive hospitality zones or sequin for long-throw sparkle in open squares.

-

Procure predictably: cartonized 1×10 m rolls, CE/RoHS documentation, and stable geometry streamline tenders and cross-border logistics.

Architecture & Materials (Optical, Mechanical, Finish)

Optical — The ~92% light transmission helps preserve luminous flux while mitigating shadowing from brackets and conductors; when viewers stand close or gradients must appear smooth, installers can encrypt LED spacing toward ~3 cm without changing the base grid logic.

Mechanical — The pvc mesh folds and bends to accommodate corners, curves, and cable routes; with mechanical fixing at edges and mid-spans, crews prevent sagging and keep seams tight in open air.

Finish — Frosted reduces glare and evens luminance for indoor canopies and hotel lobbies; sequin amplifies sparkle and perceived brightness for façades or rooftops visible from distance.

Electrical Integration Checklist (for BOM & Shop Drawings)

-

Voltage class: lock one of DC 6 V / 12 V / 24 V per site before production; mixing voltages risks uneven dimming and controller trips.

-

Controller capacity: verify channel current, address count, and safety margins for static and dynamic-tracking modes.

-

Chain length & drop: model voltage drop at peak effect; standardize harness gauges and injection points to keep color uniform.

-

Dimming curves: align gamma or PWM profiles across controllers so sparkle effects look coherent across seams.

-

Labeling & handover: label strings, document addresses, and archive CAD aperture maps for next-season reuse and fast troubleshooting.

Installation Workflow (Field-Proven, Fast, and Repeatable)

-

Pre-survey & mock-up — Confirm viewing distances, wind exposure, drainage, and maintenance access; mock up one panel to settle spacing and finish.

-

CAD layout — Import the 6 cm grid, trace motif contours, and pre-assign module counts; mark encrypted zones (~3 cm) only where needed.

-

Cutting & staging — Pre-cut 1×10 m rolls to bay sizes; stage by elevation or façade zone to minimize crane or lift repositioning.

-

Mechanical fixing — Secure edges and mid-spans first; add trims or gaskets at penetrations and terminations to protect cables.

-

Electrical hookup — Route harnesses along the grid; inject power where drop margins require; strain-relieve at connectors.

-

Commissioning — Address controllers, validate static scenes, then bring up dynamic tracking; record brightness setpoints and effect timings.

Application Playbooks (How Different Sites Use the pvc mesh)

Municipal Squares — Use sequin finish for long-throw sparkle; keep encrypted spacing only in focal motifs to balance cost and uniformity; the IP65 + climate rating supports open-air festivals.

Theme Hotels — Choose frosted finish for porte-cochères, lobbies, and canopies where guests stand close; route cables along the 6 cm grid to keep service panels clean.

Commercial Complexes — For atriums and promenades, splice multi-roll arrays past 50 m²; document seams and controller zones for consistent effects across floors.

Event Contractors — Reuse jigs, fastening hardware, and CAD aperture maps from previous venues; cartonized 1×10 m rolls aid rapid mobilization across cities.

Product Parameters

| Parameter | Specification |

|---|---|

| Base Material | UV-resistant pvc mesh carpet; ~92% light transmission |

| Aperture | Regular 6 cm; customizable per motif |

| Roll Size | 1×10 m per carton; optional 1×5 m |

| Flexibility | Easy to bend for rapid paving and mechanical fixing |

| LED Module Fit | Dense modules; spacing encryptable to ~3 cm on 6 cm baseline |

| Protection | IP65 dust- and water-resistant |

| Operating Temp | −20 °C to 70 °C |

| Surface Options | Frosted / Sequin double coating (optional) |

| Splicing Coverage | Multi-roll arrays to 50 m²+ (typical) |

| Certifications | CE / RoHS |

| Voltage (per BOM) | DC 6 V / 12 V / 24 V |

Procurement, Logistics & Standardization

Because geometry and roll size are consistent, procurement can place predictable POs and lock freight plans early; warehouses can kit by façade zone; and installers can repeat the same fastening playbook across venues. Consequently, handover packs remain uniform year-to-year, which reduces training time for seasonal crews. Additionally, CE/RoHS paperwork accelerates tender approvals and customs clearance for cross-border programs.

QA & Compliance (Keep Projects Audit-Ready)

-

Ingress & climate: maintain IP65 protections at penetrations; verify −20 °C~70 °C component ratings across the entire chain, including connectors.

-

Uniformity targets: specify luminance variance and allow encrypted spacing only where viewers stand close; validate with a small onsite test before mass build.

-

Documentation: include aperture drawings, controller addresses, and maintenance access notes in as-built packs; archive for next season.

FAQ (Engineer-Focused)

Q1: How should we choose LED spacing for different viewing distances?

Start with the regular 6 cm grid; where viewers stand close or gradients must look continuous, encrypt toward ~3 cm only in those zones to control cost and thermal load.

Q2: Can this base tolerate winter storms and summer heat?

Yes. The mesh operates from −20 °C to 70 °C and carries IP65 resistance to dust and water ingress for outdoor deployments.

Q3: What if our city uses different voltage ecosystems?

Pick a single voltage class per site—DC 6 V, 12 V, or 24 V—and size controllers accordingly; mixing voltages on one façade risks uneven dimming and protection trips.

Q4: Which finish should we select—frosted or sequin?

Use frosted where glare control matters and viewers are close; choose sequin where long-throw sparkle adds impact without higher current.

Q5: How do we speed repeat projects?

Reuse CAD aperture maps, jig dimensions, and fastening patterns; stage 1×10 m rolls by elevation to cut lift moves; keep handover logs for addresses and service points.