The Definitive Guide to 3D Motif Light Material

3D LED Motif Light Sculpture with Gifts and Ribbon Design

The Definitive White Paper on 3D Motif Light Material

You are about to approve a significant outdoor lighting project. The aesthetics are confirmed. But a single line item in the technical specifications will dictate the long-term success or failure of this entire venture: the 3D motif light material. This choice will determine if your project becomes a celebrated landmark or a rusted, hazardous liability.

This document is not a marketing brochure. It is a technical white paper from our engineering department. We move beyond claims to provide the verifiable data your engineering, procurement, and finance teams require to make a fully informed, risk-averse decision. For a broader overview of design choices, you may wish to first review our foundational 2D vs. 3D Motif Lights Manufacturer’s Guide.

Executive Summary for C-Level Decision-Makers

Ⅰ.The Core Decision: The choice of 3D motif light material for the frame dictates the asset’s lifespan, safety profile, and Total Cost of Ownership (TCO).

Ⅱ.Steel is a High-Risk Liability: Its corrosion protection depends entirely on a fragile, applied coating. A single point of failure guarantees structural decay.

Ⅲ.Aluminum is a Low-Risk Asset: 6061-T6 aluminum possesses inherent, self-healing corrosion protection, making it the superior long-term investment.

Ⅳ.The Financial Case is Clear: While steel has a lower upfront cost, aluminum’s significant savings in shipping, installation, and zero required maintenance lead to a substantially lower TCO and higher ROI over a 10-year horizon.

Ⅴ.This Document Provides Proof: All claims herein are backed by verifiable data from international testing standards like ASTM B117 and ISO 12944.

The Fundamental Engineering Principle: Inherent vs. Applied Protection

The entire debate between these two materials hinges on one critical concept:

Steel’s protection is APPLIED. It is entirely reliant on an external shield of powder coating. Think of it as armor with a flaw. Once a deep scratch, stone chip, or installation scuff breaches this armor, moisture creeps underneath. This process, called undercutting, initiates a hidden, irreversible decay of the raw steel.

This specific corrosion vulnerability is the single most common reason for on-site asset failure. It is, however, just one of several critical risks a procurement team must mitigate.

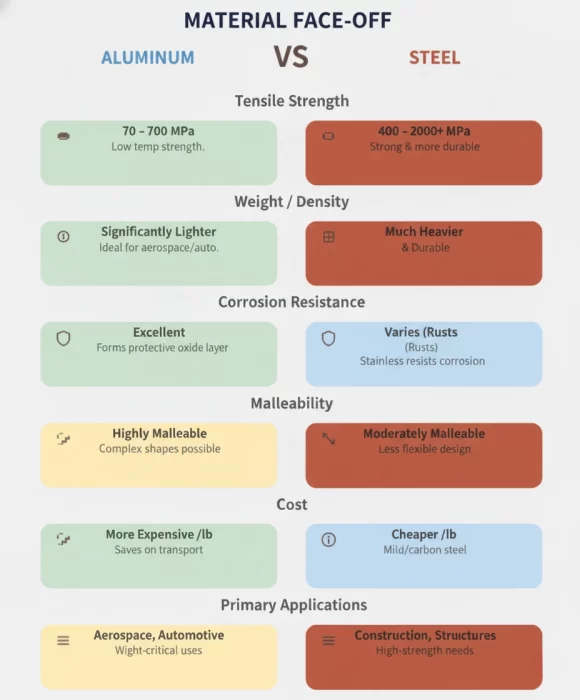

Aluminum vs Steel Material Comparison for Structural Applications

【Read our complete guide on Common Failures in Large 3D LED Sculptures (and How We Prevent Them)】 to understand the full risk profile, including electrical and fading issues.

Aluminum’s protection is INHERENT. The material itself is the defense. When 6061-T6 aluminum is exposed to air, it instantly forms a tough, transparent, and self-healing layer of aluminum oxide. If this layer is scratched, a new one forms immediately. It does not need external armor because its own skin is its shield. This single property eliminates the primary failure mode of steel.

Technical Comparison: 6061-T6 Aluminum vs. Structural Steel

| Characteristic | 6061-T6 Aluminum Frame | Anti-Rust Coated Steel Frame |

|---|---|---|

| Material Grade | Aerospace-Grade 6061-T6 Alloy | Q235 Structural Steel (Typical) |

| Protective Mechanism | Inherent (Self-healing oxide layer) | Applied (External powder coat) |

| Corrosion Resistance | Permanent. Passes ASTM B117 > 1000 hrs. | Vulnerable. Fails upon coating breach. |

| Density (kg/m³)¹ | ~2,700 | ~7,850 |

| Relative Weight | 1.0x | ~2.9x |

| Strength-to-Weight Ratio | Excellent. | Good. |

| Weld Integrity Standard | Superior. TIG Welding (AWS D1.2) | Standard. MIG Welding (AWS D1.1) |

| Primary Failure Mode | Extremely low risk (Improper design) | High risk (Coating failure & corrosion) |

| Recommended Environment | All environments, including coastal/industrial | Controlled, dry, low-impact environments |

The standards listed above (ASTM, ISO, AWS) confirm the structural integrity of the frame. This must be paired with equally rigorous electrical protection.

A high-quality aluminum frame is the foundation, but its longevity is only secured by robust waterproofing against rain, snow, and humidity. The frame’s design is, in fact, critical to protecting connectors and power supplies.

【Explore our technical guide on IP67 Waterproofing for 3D LED Sculptures: What B2B Buyers Need to Know】to understand how these systems work together.

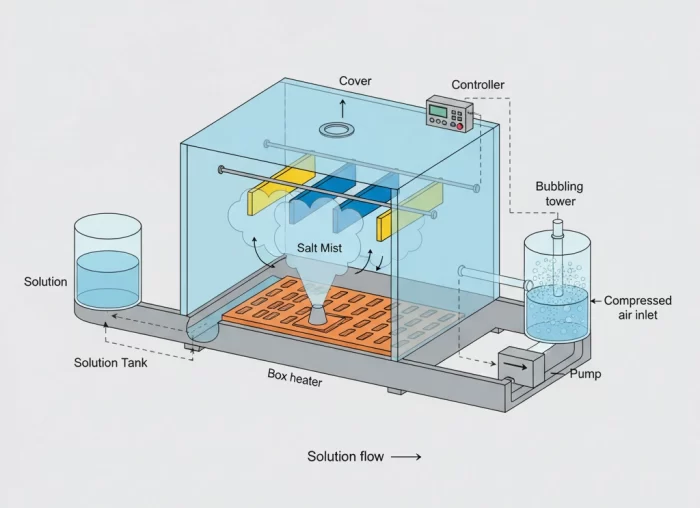

Verification: Test Data & Compliance Standards

We validate performance through adherence to rigorous international standards. This is our commitment to engineering transparency.

| Standard / Test | Purpose & Relevance | Our Result / Compliance |

|---|---|---|

| ASTM B117 | Neutral Salt Spray Test for corrosion resistance. | Our powder-coated 6061-T6 samples consistently exceed 1,000 hours with no significant corrosion. |

| ISO 12944 | Protective paint systems for steel structures. | We apply coating systems rated for C4/C5 environments, but acknowledge the inherent risk of coating breach. |

| AWS D1.2 / D1.1 | Structural Welding Code for Aluminum / Steel. | Our welders are certified to these standards, ensuring maximum joint integrity. |

| ISO 9001:2015 | Quality Management Systems. | Our factory operations are certified, ensuring process control and product consistency. |

| CE / RoHS | European Market Compliance. | Products meet EU safety, health, and environmental standards. |

| UL / ETL | North American Safety Standards. | All electrical components are listed, ensuring compliance and safety. |

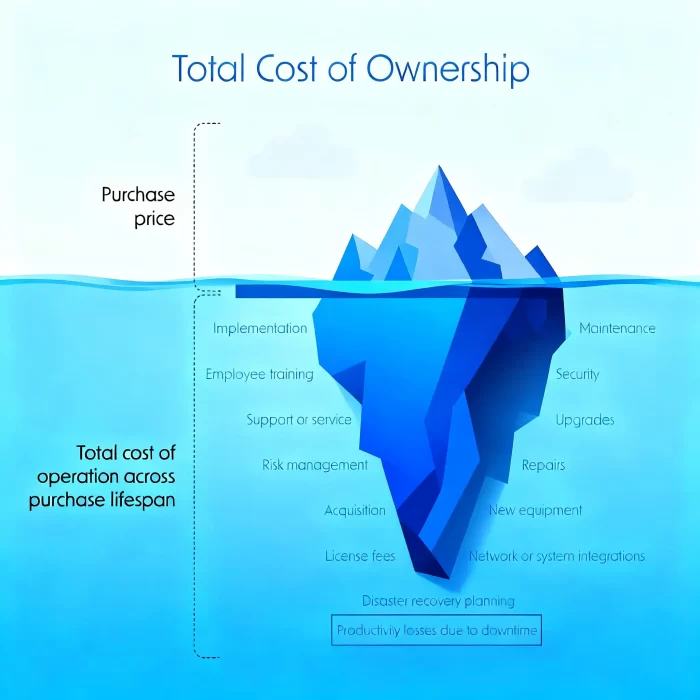

The Financial Truth: 10-Year Total Cost of Ownership (TCO) Model

The initial purchase price is a misleading metric. A comprehensive TCO analysis reveals the true, long-term financial impact of your 3D motif light material choice.

| Cost Factor | Anti-Rust Steel Frame | Aluminum Frame for Motif Lights | Financial Impact Analysis |

|---|---|---|---|

| Upfront Material Cost | Baseline (1.0x) | Higher (~1.5x – 2.0x) | Steel appears cheaper at procurement. |

| Shipping & Logistics¹ | High | Low (Saves 40-60%) | Aluminum’s low weight yields immediate, substantial freight savings. |

| Installation Labor & Equip.¹ | High | Low (Saves 30-50%) | Lighter frames mean smaller crews, less crane time, and faster, safer installation. |

| 10-Yr Maintenance Cost | Medium | Near-Zero | Steel requires annual inspections and rust mitigation. Aluminum requires only basic cleaning. |

| Risk & Liability Cost | Medium-High | Extremely Low | The potential cost of a rust-induced structural failure (replacement, damages, reputation) is a significant liability for steel. |

| 10-Year TCO Result | Higher | Lower | Aluminum provides a superior ROI and a significantly lower Total Cost of Ownership. |

Engineering Boundaries & Application Matrix

To ensure optimal performance, a professional supplier must also define the operational boundaries. Aluminum is a superior material, not a magic one. The following protocols are essential for guaranteeing the longevity and safety of the structure in specific, demanding environments.

•Mitigating Risks in Coastal & High-Salt Environments

In environments with high salt spray, such as coastal regions, we specify 6061-T6 aluminum protected by a dual-layer system. This involves either a marine-grade powder coating or a thick-film anodizing process to provide maximum, long-lasting defense against salt-induced corrosion.

•Performance in High-Pollution Industrial Zones

For installations in industrial zones with high levels of airborne pollutants, a chemical-resistant powder coating over the 6061-T6 aluminum is essential. We also advise a regular, pH-neutral cleaning schedule to prevent the accumulation of acidic deposits.

•Preventing Galvanic Corrosion: Mixed-Metal Connections

This is a critical, non-negotiable engineering protocol. To prevent galvanic corrosion—an electrochemical reaction that occurs when dissimilar metals are in contact—all connections must use stainless steel (304/316 grade) fasteners. Crucially, these fasteners are isolated from the aluminum frame using non-conductive nylon or Teflon insulating washers and bushings.

Corroded Steel Fastener with Rust on Metal Surface

•Ensuring Structural Integrity: Post-Weld Heat Treatment

Welding introduces a Heat-Affected Zone (HAZ) which can alter the material’s temper. For structures with critical load-bearing requirements, we can perform a full-frame post-weld heat treatment. This process restores the entire component to its full T6 temper, guaranteeing uniform strength and eliminating any potential weaknesses from the HAZ.

Expanded FAQ: Answering Your Engineer’s Questions

Q1: How do you prevent electrochemical (galvanic) corrosion where aluminum contacts other metals? This is a critical engineering detail. We mandate the use of stainless steel fasteners (304 or 316 grade) and, most importantly, isolate the contact points with non-conductive polymer or Teflon washers and bushings. This breaks the electrical circuit and stops galvanic corrosion before it can start.

Q2: How does the thermal expansion/contraction of aluminum compare to steel in extreme climates? Aluminum’s coefficient of thermal expansion is roughly twice that of steel. Our engineers account for this at the design stage by engineering expansion joints and using slotted connections for very large structures, ensuring structural integrity across all temperature ranges.

Q3: Which is more durable in a coastal environment: anodizing or powder coating on aluminum? For pure corrosion resistance, a properly sealed, thick-film anodized layer is superior. However, marine-grade powder coating offers a wider range of colors and better UV resistance. For ultimate protection, we can provide a system with both: an anodized base layer followed by a powder topcoat.

Q4: For the “self-healing” oxide layer, what are its limitations? The passive oxide layer is incredibly effective against atmospheric corrosion. However, it can be compromised by highly acidic or alkaline chemicals (e.g., harsh industrial cleaners). That is why we provide a clear maintenance guide specifying pH-neutral cleaning agents.

Proven Performance: A B2B Application Case

Before our final recommendation, consider this real-world application. For clients managing large-scale municipal installations in high-salt coastal zones (e.g., Middle East, Southeast Asia), the 6061-T6 frame has a proven zero-failure record over a five-year service life. This performance ensures your city’s landmark remains a symbol of quality, not a maintenance burden.

Illuminated 3D LED Motif Light Sculpture in the Shape of a Lotus Flower

Our Final, Unwavering Recommendation

The verifiable data, long-term financial modeling, and fundamental material science all point to a single, unequivocal conclusion.

For any professional B2B client whose reputation is tied to quality, safety, and long-term value, the 6061-T6 aluminum frame is the only responsible choice for an outdoor 3D motif light material. It is an investment in certainty.

Explore our portfolio of high-performance 3D LED Motif Lights to see these principles in action.

Take the Next Step Towards a Risk-Free, High-ROI Project.

Our engineering team is ready to support your decision-making process with transparent data.